High Density Chopping Boards

Commercial High Density Chopping Boards are essential workhorses in professional kitchens across the UK. Made from durable HDPE (High-Density Polyethylene), these boards provide the perfect cutting surface for busy chefs in restaurants, hotels, and catering operations. Unlike domestic boards, these commercial-grade champions resist knife damage, withstand intensive daily use, and help maintain crucial food safety standards through colour-coding systems. They pair perfectly with professional knives and kitchen utensils to create an efficient prep station. After 50 years of supplying the industry, we've seen how the right chopping board transforms food preparation—boosting efficiency, hygiene, and safety!

-

High Density Chopping Board | Small Kitchen Cutting Board | Food Preparation Surface | Hygiplas HC869

In Stock

Box of 6

Hygiplas

Easy to clean

High Density Polyethylene

£53.99 £116.76 -

High Density Anti-Bacterial Chopping Boards | Commercial Kitchen Cutting Boards | Set of 6 Large Boards | Hygiplas HC862

In Stock

Box of 6

Hygiplas

Green - salad and fruit

High Density Polyethylene

£78.99 £169.50 -

Commercial Chopping Board Set | High Density Cutting Boards | Standard Set | Hygiplas S237

12.2 kgIn Stock

1/2(H)x 18(W)x 12(L)/ 12 x 455 x 305mm

Hygiplas

High Density Polyethylene

£85.99 £184.59 -

High Density Chopping Board Set | Extra Large Cutting Boards | HACCP Color-Coded Kitchen Boards | Hygiplas S242

41.96kgIn Stock

1(H)x 23 1/2(W)x 17 3/4(L)/ 24 x 600 x 450mm

Hygiplas

Six coloured boards for different food types

High Density Polyethylene

£308.99 £663.03

Commercial High Density Chopping Boards for Professional Kitchens

Brands Trusted by Industry Professionals

Key Features and Benefits

- High-Density Material HDPE construction offers exceptional durability—stands up to years of heavy chopping.

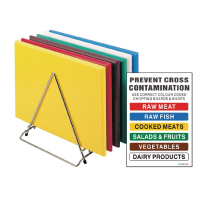

- Colour-Coded System Prevents cross-contamination—critical for food safety compliance.

- Non-Porous Surface Resists bacteria growth and absorption—maintains strict hygiene standards.

- Dishwasher Safe Withstands high-temperature washing—simplifies sanitisation procedures.

- Knife-Friendly Surface Protects blade edges while providing ideal cutting resistance.

- Shock Absorption Reduces wrist fatigue during extended prep sessions.

- Non-Slip Options Stays firmly in place—enhances safety during fast-paced prep.

- Long Service Life Sustainable investment—outlasts budget alternatives by years.

Essential Buying Considerations

Size and Thickness

- Standard 450x300mm size suits most prep stations—check your workspace.

- Thicker 20-25mm boards provide stability for heavy-duty tasks.

- Consider multiple smaller boards for limited counter space.

Colour Coding and Usage

- Follow standard colour systems—matches with knife handles.

- Choose boards with grip feet for wet work areas.

- Consider grooved boards for high-juice ingredients.

How Commercial High Density Chopping Boards Work

Commercial high density chopping boards are crafted from HDPE—a robust, non-porous plastic that strikes the perfect balance between protecting knife edges and withstanding constant use. The material doesn't harbour bacteria in the same way wooden boards might, while offering a gentle-yet-firm cutting surface. Available in industry-standard colours for different food types (red for raw meat, blue for fish, etc.), they create a visual safety system in busy kitchens. The dense structure prevents deep scoring, which helps maintain hygiene standards, while the non-absorbent surface means juices won't penetrate—critical for preventing cross-contamination in professional environments.

Trusted Insights from Charlotte Westwood

![]()

Chef Tools & Kitchenware Specialist

10 years experience

Safety Guidelines

- Regular Inspection Check for deep grooves—harbours harmful bacteria.

- Strict Coding Never mix colour uses—prevents dangerous cross-contamination.

- Proper Cleaning Sanitise after each use—maintains hygiene standards.

- Secure Placement Use non-slip mats underneath—prevents accidents.

- Vertical Storage Store upright—allows complete drying.

- Replace When Scored Retire heavily grooved boards—safety first.

Top Tips for Using Commercial High Density Chopping Boards

To maximise the lifespan of your HDPE boards, rotate them regularly to ensure even wear across the surface. After heavy use, scrub with a stiff brush and sanitiser rather than bleach, which can damage the material over time. Consider using board scrapers to remove stubborn food particles, and store boards vertically in a dedicated rack to allow proper air circulation and prevent moisture buildup. Regularly inspect for deep scores that might harbour bacteria—when in doubt, replace!

Benefits of Using Commercial High Density Chopping Boards

- Enhanced Food Safety Colour-coding prevents cross-contamination—critical for inspections.

- Improved Efficiency Durable surface enables faster, more confident cutting.

- Cost-Effective Outlasts cheaper alternatives—better value long-term.

Did You Know?

- Longevity Quality HDPE boards last 2-3 times longer than standard plastic.

- Temperature Resistance Withstands -40°C to 80°C—versatile for all kitchen environments.

- Hygiene Standards Professional kitchens typically need 6+ boards to meet safety regulations.

- Replacement Schedule Top chefs replace boards every 6-12 months—ensures optimal hygiene.

Expert Insights on Commercial High Density Chopping Boards

With five decades in the trade, we've seen chopping boards evolve tremendously. 'A quality HDPE board isn't just about cutting—it's about building a food safety system,' explains Mark, our kitchen equipment specialist. 'In professional kitchens, the colour-coding isn't optional; it's essential for maintaining standards during busy service.'

- Pros: Hygienic, durable, dishwasher-safe, helps maintain compliance.

- Cons: Requires regular replacement once heavily scored—budget accordingly.

Who Needs Commercial High Density Chopping Boards?

- Restaurants Essential for organised prep stations—enhances workflow efficiency.

- Hotels Perfect for high-volume breakfast and banquet preparations.

- Culinary Schools Teaches proper food safety practices—industry-standard equipment.

- Healthcare Kitchens Critical for maintaining stringent hygiene for vulnerable populations.

Real-World Success with Commercial High Density Chopping Boards

The bustling kitchen at The Copper Kettle in Bristol faced constant challenges with cross-contamination risks during their busy lunch service. After consulting with our team, they implemented a full colour-coded system with heavy-duty HDPE boards and matching knife handles. 'It's transformed our operation,' says head chef Daniel. 'Staff immediately know which boards to use, prep is faster, and our last health inspection was a breeze—the inspector specifically commented on our excellent board system!'

FAQs

- How often should I replace commercial chopping boards? Replace when surfaces show deep scoring—typically every 6-12 months in busy kitchens.

- What's the difference between HDPE and PE boards? HDPE offers superior density and durability—worth the extra investment for professional use.

- Are coloured boards required by food safety regulations? While not explicitly required, they help demonstrate due diligence in preventing cross-contamination.

- Can I use the same board for different food types? Not recommended—separate colour-coded boards are essential for food safety compliance.

- What's the best way to sanitise HDPE boards? Hot water with commercial sanitiser, then rinse thoroughly—avoid prolonged chemical exposure.

- Do commercial boards need special storage? Ideally stored vertically in dedicated racks—promotes airflow and prevents moisture buildup.

Looking for Equipment by Business Type?

Not sure where to start? Whether you're running a bustling café, opening a pizzeria, or managing a school canteen, we've made it easy to shop by business type. Explore handpicked equipment bundles and essentials tailored to your industry—saving you time and making sure you get exactly what you need.

Other Categories You Might Find Useful

We’ve selected some closely related categories that might be essential for your setup. Whether you’re expanding your kitchen or just making sure you’ve got everything covered, these links will help you explore more equipment that fits your needs.

What our Customers Say

'These boards have revolutionised our kitchen hygiene system—absolute quality!'

J James Head Chef, The Riverside Grill, Leeds'Sturdy, hygienic and the colour-coding is spot on for our busy kitchen!'

M Mira Kitchen Manager, The Crown Hotel, Birmingham

Why Choose EasyEquipment for Commercial High Density Chopping Boards?

- Trusted Supplier Supplying professional kitchens for 50 years—proven expertise.

- Fast Delivery Next-day options available across the UK—no waiting.

- Best Price Promise Value without compromising quality—competitive market rates.

- Expert Guidance Talk to specialists who understand commercial kitchen requirements.

Ready to Explore Commercial High Density Chopping Boards?

Upgrade your kitchen's food safety system with our professional-grade HDPE chopping boards. With colour-coding options, various sizes, and hygienic designs, you'll find the perfect solution for your commercial kitchen. Get in touch with our experts today!

#HDPEChoppingBoards

- #CommercialKitchenEquipment

- #FoodSafety

- #ColourCodedBoards

- #ProfessionalKitchen

- #ChefEssentials

- #EasyEquipment